Products List

- CNC Vertical Lathe

- Single Column CNC Vertical Lathe

- Single Column CNC Vertical Lathe (Economical Type)

- Single Column CNC Vertical Lathe (Professional Type)

- High Speed CNC Vertical Lathe

- CNC Turning Center

- Double Column CNC Vertical Lathe

- CNC Turning and Milling Center

- Single Column CNC Turning and Milling Compound Center

- Double Column CNC Turning and Milling Compound Center

- Vertical Lathe

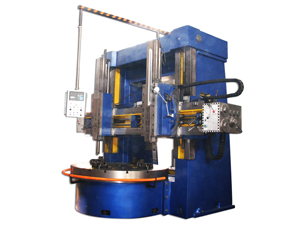

Double Column Vertical Lathe

Description of Double Column Vertical Lathe

With the adoption of independent hydraulic station modular design, our double column vertical lathe is suitable for processing hard alloy, ceramic cutting tools, ferrous metal, nonferrous metal and some non-metallic parts of the inner and outer cylinder, inner and outer conical surface, end face, grooving for rough and finish machining.Features of Double Column Vertical Lathe

1. Based on the modular design, our China double column turning lathe has stable and reliable performance.2. Being processed by thermal aging treatment, our China double column turning lathe has high quality.

3. The surface of cross beam is processed by supersonic frequency quenching. Its guide way is sliding and rolling compound type. The vertical tool post uses ductile cast iron and the surface of sliding is with plastic belt, which is durable and lasting,

4. The auto lubrication pump of double column vertical lathe can lubricate each part automatically.

5. China double column turning lathe has Japan Omron PLC control system and has high quality electrical parts.

6. It has two working ways, dynamic & static pressure guide way with 10 tons loading capacity and pure static pressure guide way with 16-20 tons loading capacity.

7. Its independent hydraulic station with grating display device is easy to adjust, repair and maintain.

8. The high precision variable speed gear (6 grade) and grinding spiral level gear (7 grade) have the characters of low noise and smooth running.

9. This double column vertical lathe carries out JB/T4116-96 CNC vertical lathe precision inspection and JB/3665-96 CNC vertical lathe technical condition.

10. The perfect processing and assembly technology of China double column turning lathe guarantee its super quality.

11. It concludes types of

|

C5225E |

C5228E |

C5231E |

C5235E |

CQ5240E |

CJ5240 |

CJ5250 |

Typical of C5225E Single Column Vertical Lathe specification

| Term | Unit | C5225E | |

| Max. turning diameter | mm | 2500 | |

| Worktable diameter | mm | 2250 | |

| Max. height of work piece | mm | 1600/2000/2500 | |

| Max. weight of work piece | t. | 10/16 | |

| Max. cutting force of right tool post | KN | 35 | |

| Max. cutting force of left tool post | KN | 30 | |

| Max. total cutting force | KN | 65 | |

| Max. torque of worktable | KN | 63 | |

| Stage number of variable speed of worktable | 16 | ||

| Variable speed range of worktable | r/min | 2-63 | |

| Feeding range of tool post | mm /min | 0.25-90 | |

| Horizontal travel of tool post | mm | 1400 | |

| Vertical travel of tool post | mm | 1000/1250 | |

| Crossbeam moving speed | mm /min | 350 | |

| Tool post rapid moving speed | mm /min | 1560 | |

| Max. swivel angle of worktable | 。 | +30 | |

| Main electric motor power | KW | 55 | |

| Weight of worktable | t. | 32/35/37 | |