Products List

- CNC Vertical Lathe

- Single Column CNC Vertical Lathe

- Single Column CNC Vertical Lathe (Economical Type)

- Single Column CNC Vertical Lathe (Professional Type)

- High Speed CNC Vertical Lathe

- CNC Turning Center

- Double Column CNC Vertical Lathe

- CNC Turning and Milling Center

- Single Column CNC Turning and Milling Compound Center

- Double Column CNC Turning and Milling Compound Center

- Vertical Lathe

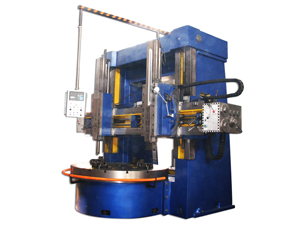

- Single Column Vertical LatheSingle column vertical lathe has good quality, safe and reliable performance. As a single column lathe machine manufacturer, our company stands in the leading position in China’s lathe market. This machine is applied in a variety of small ring unit, shell, fla...

- Double Column Vertical LatheWith the adoption of independent hydraulic station modular design, our double column vertical lathe is suitable for processing hard alloy, ceramic cutting tools, ferrous metal, nonferrous metal and some non-metallic parts of the inner and outer cylinder, inner...

Vertical Lathe

Descriptions of vertical turning lathe

As a kind of metal turning equipment, the single-column and double column vertical lathe is widely used to all sectors of the mechanical processing, like internal and external cylindrical surface, conical surface, and end surface, grooving and cutting processing. This processing consists of rough machining and fine machining. The CNC vertical lathe type can process the materials into a variety of curved surfaces, thread and so on easily.Features of vertical turning lathe

1. Quality of our vertical lathe is beyond domestic market level because of its perfect technology, machining and assembly process.2. Crossbeam guide beam and ram guide are quenched by supersonic frequency (HR>50). The wearable band sticking on the sliding surface sustains its precision and ensures its long life.

3. High quality casting by thermal aging treatment would not lose its weight.

4. Five angle tool carriers of vertical turning lathe adopt high precision girth coupling. This coupling has 120 equal dividing, positioning and perfect rigidity.

5. We have two axis digital displays for standard configurations. However, four axis digital displays of vertical lathe are optional.

6. Our products adopt high quality electric components and Japan Omron PLC control standardized wiring process. It has high reliability.

7. Being equipped with electric rotary valve and 16 grade mechanical varied speeds, our vertical lathe is more convenient, flexible and reliable.

8. Our high precision grinding gears and grinding bevel gear (6 grades) have the features of low noise and smooth running.

9. Our vertical turning lathe has excellent quality because of its perfect processing and assembly technology.

10. Our machine carried out JB/T4116-96 vertical lathe precision inspection and JB/3665-96 vertical lathe technical condition.

11. Our machine is equipped with complete configuration and has perfect after-sales service.

12. The following functions are optional for our vertical turning lathe : German Mecano button station, lengthened ram and heightened bed, etc

13. Our vertical lathe has the types of C5112E, C5116E, C5120E, C5123E, and C5126E.

Specification of C5112E

| Term | Unit | C5112E |

| Max. turning diameter of vertical tool post | mm | 1250 |

| Max. turning diameter of side tool post | mm | 1100 |

| Worktable diameter | mm | 1000 |

| Max. height of work piece | mm | 1000/1200 |

| Max. weight of work piece | t. | 3.2 |

| Max. cutting force of vertical tool post | KN | 20 |

| Max. cutting force of side tool post | KN | 20 |

| Max. total cutting force | KN | 35 |

| Max. torque of worktable | KN | 17.5 |

| Stage number of variable speed of worktable | 16 | |

| Variable speed range of worktable | r/min | 6.3-200 |

| Feeding stage number of vertical and side tool post | 12 | |

| Feeding range of vertical and side tool post | mm/min | 0.8-86 |

| Horizontal travel of vertical tool post | mm | 700 |

| Vertical travel of vertical tool post | mm | 650 |

| Horizontal travel of side tool post | mm | 630 |

| Vertical travel of side tool post | mm | 900 |

| Crossbeam travel | mm | 650 |

| Vertical and side Tool post rapid moving speed | mm/min | 1800 |

| Max. swivel angle of worktable | 。 | +30 |

| Crossbeam lifting speed | mm/min | 440 |

| Sectional dimension of tool bar | mm | 40×40 |

| Feeding electric motor power | KW | 1.3/1.8 |

| Main electric motor power | KW | 22 |

| Overall size | mm | 2360×2277×3403 |

| Weight of worktable | t | 8 |